Ryegate Associates

Established in 1992, Ryegate Associates has remained at the forefront of local power provision, overseeing the operation of an advanced 20 MW wood-fired electrical power (biomass) generation facility.

As a baseload electrical generation plant, our facility consistently operates at or near total capacity, ensuring a dependable and uninterrupted power supply to our esteemed customers. The sole exceptions to this steadfast commitment are scheduled maintenance periods, during which we meticulously optimize the plant’s performance.

At the heart of Ryegate Associates lies a profound sense of pride in our enduring legacy of empowering the local community. With our state-of-the-art facility and unwavering commitment to environmental responsibility, we steadfastly establish the gold standard for sustainable power generation.

Ryegate Power Generation Facility takes immense pride in employing a dedicated team of 21 individuals, many of whom call the local area their home. Within our team, a regulatory forester plays a pivotal role, ensuring stringent adherence to the Vermont Harvesting Regulations, underscoring our dedication to responsible forestry practices.

In our ceaseless pursuit of sustainable energy solutions, we take pride in producing and delivering an impressive 250,000 tons of whole tree chips annually, substantially contributing to the renewable energy sector. Furthermore, our annual distribution of over 4,000 tons of wood ash finds valuable applications in various recycling programs, including its use as organic fertilizer for local farmers. This not only fosters waste reduction but also bolsters the agricultural community.

Power Plant

1. Key Highlights

- Ryegate Associates, which owns the Ryegate plant, is a partnership owned 99.9% Ryegate Holdings LLC and 0.1% by Capergy US LLC.

- Vermont’s electricity generation comes almost entirely from renewable resources. Half of generation is hydroelectric, and one-fifth is derived from biomass (wood and wood waste).

- Provide an important environmentally responsible forest management solution as well as substantial value chain benefits to local timber industry.

- Strong fuel supply: strong long-term historical relationships with suppliers for over 30 years and substantial on-site fuel storage

- Strong operations: history of safe, strong, reliable operation with highly experienced team

- Contracted Electricity Sale: Power Purchase Agreement extended until October 2032 based on ACT155.

2. Asset Overview

| Plant Overview | |

| Location | East Ryegate, VT |

| Net Capacity | 19.6 MW |

| Average Burn Rate | 1.60 tons/ MWh |

| Primary Fuel Type | Whole Tree Chips |

| 2023 sold Generation | 160,700 MWh |

| 2023 Fuel Burned | 263,300 tons |

| PPA Expiry | October 2032 |

| Acquisition | August 2020 |

| COD | November 1992 |

| Employees | 21 |

| Plant ISO | ISO-NE |

| Zone Name | .Z.Vermont |

| LMP Node | UN.BARRE_VT34.5RYGT |

| REC Eligibility | CT Class 1, NH Class 3 |

| Revenue Generation | |

| 2023 Average Energy Price | $110.71 |

| 2023 Average REC Price | $37.56 |

| 2023 Average Biomass Price | $39.62 |

| Total Output Sold via PPA | 100% of energy, 10% of RECs |

| PPA Client | Vermont Utilities (VEPPI) |

| PPA Commencement | 11/1/2022 |

| PPA Expiry | 10/31/2032 |

| Fuel Procurement | |

| # of Suppliers | 45+ |

| Average On-Site Fuel Supply | 21 days |

| % of Fuel from established Suppliers and Relationships (2023) |

95% |

Plant Overview

The Ryegate Plant is located in the upper Connecticut River Valley at East Ryegate, Vermont. The plant burns whole tree chips, derived locally from forest management and land clearing operations. The whole tree chips are products that if not used to generate electricity would have to be disposed of some other way. Ryegate has a qualifying small power production facility (“QF”) status pursuant to the Public Utility Regulatory Policies Act of 1978, as amended (see Ryegate Associates, Docket No. QF86-607- 009). Ryegate sells all of its electrical output to Vermont Utilities, under the terms of a PPA the PPA also includes REC sharing under which Ryegate receives 10% of the RECs generated. The Ryegate Plant is wholly owned by Ryegate Associates, a Utah General Partnership. Ryegate Holdings LLC, a wholly owned direct subsidiary of Capergy US LLC owns 99.9% of Ryegate Associates with Capergy US LLC, owning the balance of 0.1%.

The electricity generated by the plant meets the needs of approximately 20,000 households in Rural Vermont.

Ryegate Associates owns approximately 69 acres of land along the Connecticut River. The picture to the top right provides an aerial view of the plant site with approximate boundaries.

Ryegate Associates is also currently permitting the implementation of a dryer/pellet production- section 3 below- (~80,000 metric tons per year) planned to be operational end 2024. This project will allow beneficial use of the waste heat from the plant, increasing its overall efficiency and improving EBITDA by approximately from the increase of efficiency and pellets sales.

Ryegate Associates and a former developer identified potential for a 4-5 MW solar project on about 30 acres of its land. The approximate area of the contemplated project is indicated by the shaded area in the picture above.

Fuel Procurement

The Ryegate Plant burns whole tree chips, derived locally from forest management and land clearing operations. The plant burns low-quality wood which is continuously replenished through the natural forest cycles. Ryegate provides a much-needed outlet for low quality wood products which promote a healthier forest for the future.

Vermont is the Green Mountain State and is defined by its forests. Vermont law requires that its forests be managed to conserve, protect and enhance that resource. State-certified “foresters” serve the residents and businesses of VT in that effort. Ryegate’s Fuel Manager is a licensed Vermont forester and works to ensure that the plant’s fuel management is in total compliance with the state law and sustainable forestry practices.

Power Purchase Agreement

April 3, 2013 Ryegate Associates entered into a Vermont SPEED Power Purchase Agreement with VEPP Inc. (“VEPP”). The term of the PPA ran from November 1, 2012 to November 1, 2022. The levelized PPA price is $100/MWh. The PPA includes all energy and capacity. RECs are shared 10% for Ryegate Associates and 90% for Vermont Utilities. This PPA has been extended until 31st October 2032.

VEPP is a not-for-profit Vermont corporation that administers two of Vermont’s Renewable Energy Programs under contract with the Vermont Public Utility Commission. VEPP was started in 1994 as a collaboration between independent power producers and the Vermont utilities. VEPP is the Purchasing Agent for existing Public Utility Commission Rule 4.100 Projects. VEPP is also the Standard Offer Facilitator for existing and new Standard Offer Projects, of which the Ryegate PPA is one. VEPP acquires electric power from Vermont renewable resources and then distributes it to all 17 Vermont utilities on a pro rata basis.

Under the terms of the Ryegate PPA, VEPP pays to Ryegate a “Contract Rate” equal to the sum of a “Base Rate” and a “Fuel Price Adjustment”. The Fuel Price Adjustment is fuel pass-through mechanism to allow for a quarterly adjustment of the fuel price based on changes in fuel prices paid by Ryegate Associates, where additional costs or savings due to fuel price fluctuations shall be shared between Ryegate Associates and VEPP.

The quarterly adjustment of the fuel price is applied prospectively as a future rate adjustment. The fuel pass-through mechanism, to be implemented as a positive or negative adjustment to the Contract Rate, is calculated based on a “Fuel Price Benchmark” of $29/ton, an “Efficiency Factor” based on the actual fuel efficiency of the plant and a “Passthrough Percentage” that can vary between 30% and 70%. The formula for the quarterly Fuel Price Adjustment is:

= (Quarterly Fuel Price- Fuel Price Benchmark) x Efficiency Factor x Passthrough Percentage

Legislation enacted by the State of Vermont in 2022 (the “Legislation”) requires the Plant to increase its overall efficiency (ratio of mmBtu output to input) by 50% to continue to sell under the PPA (the “Efficiency Requirement”). Under the Legislation, the Plant must meet the following deadlines/criteria:

- By June 30, 2023: Submit to the PUC (a) a signed contract to utilize excess thermal heat generated at the Plant for a beneficial purpose and (b) certification by a qualified professional engineer that the proposed facility will meet the Efficiency Requirement. The Company filed these documents on June 29,2023 for the Project

- By October 1, 2025: Submit to the PUC documentation that the main components of the facility have been completed.

- By September 1, 2026: The Vermont Department of Public Service must make a recommendation that the Plant has achieved the Efficiency Requirement.

Renewable Energy Credits

The Ryegate plant is qualified for both Connecticut Class 1 and New Hampshire Class 3 RECs. RECs are shared with Vermont Utilities based on the schedule below:

| Ryegate Associates Share | VEPP Share |

| 10% | 90% |

Ryegate Associates markets and sells its RECs to third parties. Ryegate Associates does not sell RECs on a forward basis.

Technology & Major Equipment

The plant consists of a Riley-stoker boiler which is fired by whole tree chips on a vibrating hydro grate. The boiler delivers 190,000 lbs/hr at 1,250 psig to a GE steam turbine. An electrostatic precipitator and a SCR control emission. The SCR was constructed in 2014 which allowed Ryegate to qualify for additional REC classifications (CT Class I and NH Class 3).

Summary of Ryegate Plant Major Equipment

| Category | Equipment |

| Technology | Riley-stoker shaker grate |

| Turbine Generator | GE 23,000 hp, Extracting/Condensing; Lufkin Reduction Gear; GE 20,000 kVa, Air Cooled, 13,800 VAC generator |

| Transformers | Step-up transformer, 13.8kV to 34.5kV, 20,000 kVa; step-down transformer 13.8 kV to 4.16 kV; step-down transformer 4.16 kV to 480 volts |

| Plant Emissions | Opacity limited to no more than 20% for any 6 minute period in an hour; CO limited to 0.3 lb./MMBtu 90 lb./hr. on 8-hour rolling average; NOx limited to 0.075 lb./MMBtu 22.5 lb./hr. on a quarterly average and .15 lb./MMBtu 45 lb./hr on 8 hour rolling average; NH3 less than 20 PPMVDC one hour average; VOC 0.03 lb/MMBtu 9 lb/hr; filterable particulate matter .0007 Grains per DSCF corrected to 12% CO2, or .002 lb/MMBtu; total particulate matter .1 Grains per DSCF corrected to 12% CO2; 25 tons/year HAP’s; Teledyne continuous emission monitoring system; Zurn multi-clone separators; PPC electro-static precipitator; Combustion Components Associates SNCR and SCR |

| Fuel Handling | 2-Phelps truck dumps; 4 metering bin with 8 augers; 2 per bin, 2- Concrete silos700 tons each; CAT 980H, CAT 924H, Cat Skidsteer 236B, Chevy plow truck 2500, Chevy truck 2500, Subaru Forester, JD Lawn Mover x590, JD Law Mower Z910A, JD UTV Gator 625l |

| Water Treatment Plant | Hydro Pure cation and anion demineralizers 16,000-gallon storage tank |

| Cooling Water System | Custodis Ecodyne 2-cell cooling tower zero discharge; 1-pump house located on the Connecticut River; 1-deep well pumps located on property |

| Plant Controls | RS5000 |

Other Plant Requirements

- Water: Cooling water makeup comes from the Connecticut River. Wastewater is discharged to the Connecticut River under Ryegate NPDES permit.

- Ash: is provided to local farmers and landscapers for soil enhancement. Ash disposal is managed by Resource Management Inc.

3. The WHR-Dryer extension project

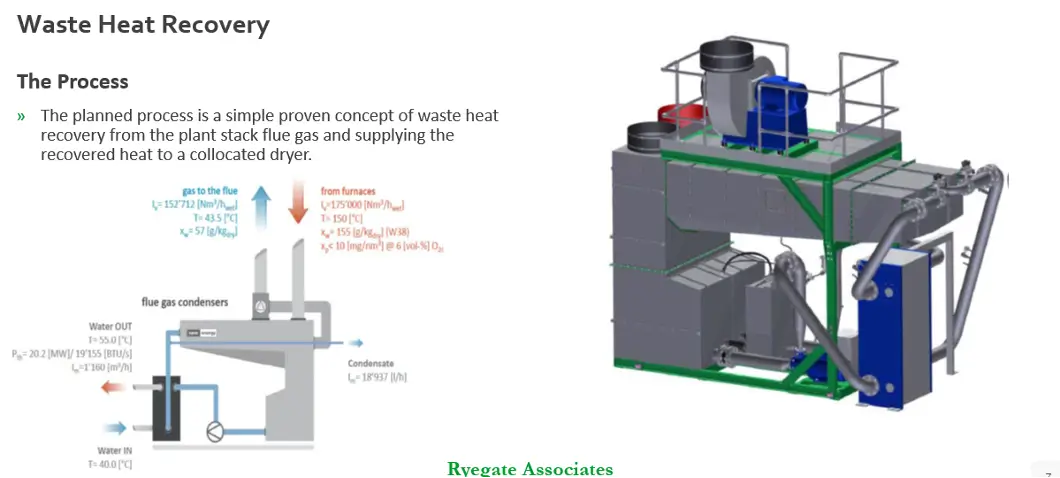

Ryegate has filed to construct a drying system to utilize low temperature heat available from the Plant stack flue gas to dry additional biomass on a low-temperature belt dryer. As required by the Legislation, a qualified professional engineer has certified its calculation that the drying system will enable the Plant to meet the Efficiency Requirement.

The output of the drying system will be dried wood chips. The Company plans to utilize these chips in 3 outlets:

1) To be sold for the heating boilers in the local market (VT, NH and ME)

2) To be converted into biochar

3) To be converted into premium pellets.

Dried woodchips, biochar and pellet manufacturing operations will benefit from a non-fossil, efficient, low-cost source of thermal energy and the Plant will generate an additional value stream from its waste heat.

Based on proposals and contracts, the total investment costs for the Project are estimated at $23M-$25M.

The Company has been awarded a $1M grant from Forest Services Wood Innovation Program for the Low temperature belt dryer and has solicited additional grants from USDA.

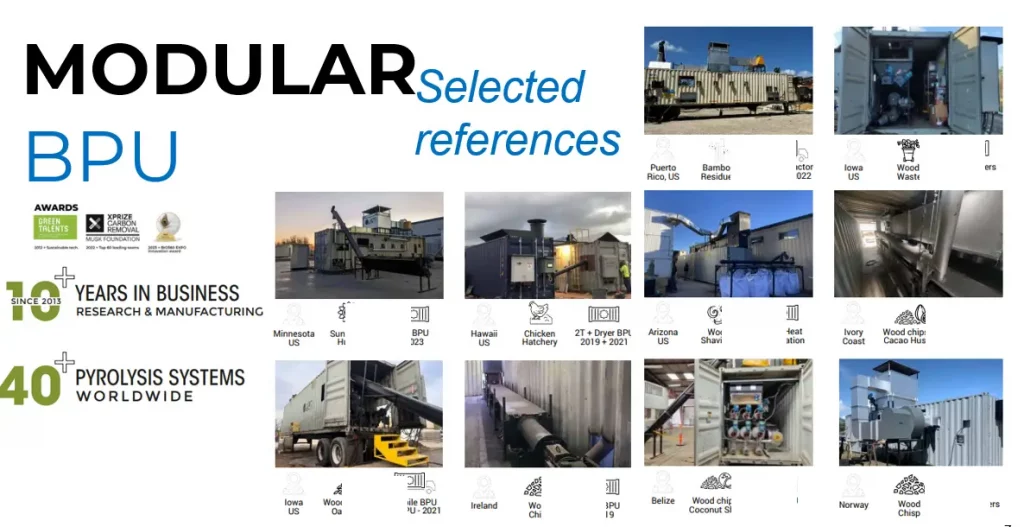

Pellet Production Project

Ryegate has filed to construct a drying system to utilize low temperature heat available from the Plant stack flue gas to dry additional biomass on a low-temperature belt dryer. As required by the Legislation, a qualified professional engineer has certified its calculation that the drying system will enable the Plant to meet the Efficiency Requirement.

The output of the drying system will be dried wood chips. The Company plans to utilize these chips to manufacture approximately 90,000 tons of wood pellets onsite using new modular pellet lines.

Pellet manufacturing operations will benefit from a non-fossil, efficient, low-cost source of thermal energy and the Plant will generate an additional value stream from its waste heat.

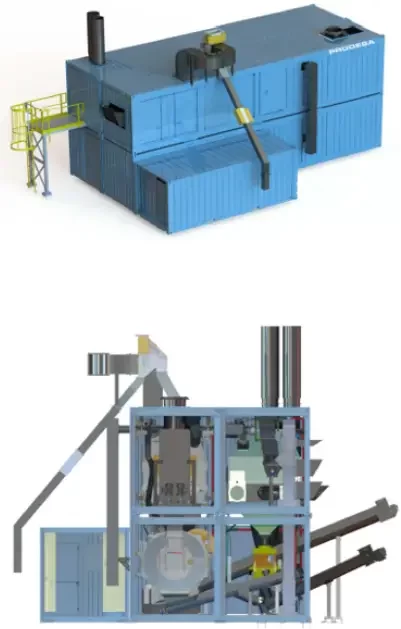

With this project, the Company will be converting the existing biomass power plant into a CHP plant to produce usable renewable heat energy by retrofitting it with the installation of a Waste Heat Recovery (WHR) module on the plant’s existing stack. This module will capture waste heat via a flue gas condensing system, which brings the flue gas leaving the plant down to its dew point in order to remove the bulk of the energy available in the stack. To ensure beneficial use of the captured heat, it will then be pumped through pre-insulated piping and supplied to a co-located low-temperature belt drying unit which will dry an estimated 20 tons of green wood chips per hour. This retrofit of the plant will increase the Ryegate Plant’s efficiency by at least 50%, meeting the requirements of Act 155, by generating an additional minimum of 315,466 mmBtu/year of heat energy.

The Belt Dryer

- Low tempreture dryer that utilizes the recovered waste heat from the power plant.

- The warm air is drawn though a bed of wood chips along a web belt.

- The warm air gently dries the wood chips which limits emission of VOCs (Volatile Organic Compounds) into the atmosphere compared to typical high temperature dryers in the region.

The biochar production

The Pellet production Unit

The biomass chips feedstock destined for the pellets production will be debarked white mill chips, different from the whole tree chips (with bark) used in the Power Plant operation, or for the dried biomass and biochar outlets. The dryer can also be used for other material, as opportunities could come.

Team

Join Our Team

Ryegate Associates is seeking talented, motivated individuals to join our team. Ryegate is an Equal Opportunity Employer and does not discriminate against any applicant or employee because of race, color, religion, gender, national origin, age, disability, veteran status, citizenship, or any other characteristic protected by applicable federal, state, or local law.

All positions require that assigned duties are performed in a safe and environmentally responsible manner.

from the blog